DAVIS KEYSEATER

Request a Quote for the Hansford Davis Keyseater

THE MODEL 15 DAVIS KEYSEATER

The Model 15 Davis Keyseater is available in two basic versions: the DA-15A, which is operated manually only, and the DA-15B, which provides the selection of manual or automatic feed and includes variable speed drive and automatic stop. Both keyseater machines include a coolant system to flush chips, a micrometer depth stop for fast and accurate depth settings, and a one-shot lubrication system.

The Model 15 Davis Keyseater uses AF or AFS cutters exclusively. Cutter change is fast because of self-centering cutter jaws and double resistance arms (one above and one below the workpiece), which make the cutters self-squaring. This rugged, gear-driven model can cut tapered keyways with the addition of the DA-58 Tilting Table and multiple keyways with the addition of the DA-22 Index Table.

For optimum cutting efficiency in large and/or long keyways and in a range of materials that vary widely in hardness, the DA-27 Variable Speed Drive accessory is recommended for the DA-15A manual version; it is standard on the DA-15B version. Other accessories are available to expand the workpiece size capacity of the Model 15 Davis Keyseater.

| Keyway Cutting Capacity | 1/16″ to 1–1/2″ (in steel) |

| Throat Depth | From face of 1” cutter to armpost: 19″ With DA-60 extra throat depth assembly: 22″ |

| Maximum Height of Work | Standard: 12″ With D-1701 arm post option: 18″ |

| Maximum Length of Cut | 16″ long cutter: 4″ 20″ long cutter: 8″ 24″ long cutter: 12″ 30″ long cutter: 18″ |

| Table Size | 20″ x 31” |

| Table Travel | 1–1/2″ |

| Strokes per Minute | Stroke: 4–1/2” Standard: 45 With DA-27 variable speed drive: 11–56 |

| Motor HP | 2 hp |

| Gross Weight | Domestic crating: 1350 lbs. Export crating: 1750 lbs. |

| Net Weight | 1250 lbs. |

| Shipping Crate Dimensions | 40″ x 44″ x 48″ |

The Davis Keyseater is unequaled by other keyseaters in terms of cutting speed and precision. Davis multiple tooth cutters allow more strokes per minute, are faster cutting than single tooth cutters, save set-up time and eliminate the length of stroke adjustments.

Davis Keyseaters have a keyway capacity of 1/16″ to 1-1/2″ wide. Using the multiple tooth cutter principle, the Davis Keyseater is the fastest cutting, most precise, and easiest-to-operate keyseater on the market.

The Hansford Davis Keyseater is one of the most versatile keyway-cutting machines available. Easy to set up, fast-cutting, and precise, the Davis Keyseater easily cuts keyways that range widely in depth and width.

Hansford’s 2024 direct list price:

Model DA-15-A Manual: *Call us for the current price.

Model DA-15-B Automatic: *Call us for the current price.

* Options, Tooling, Accessories Extra.

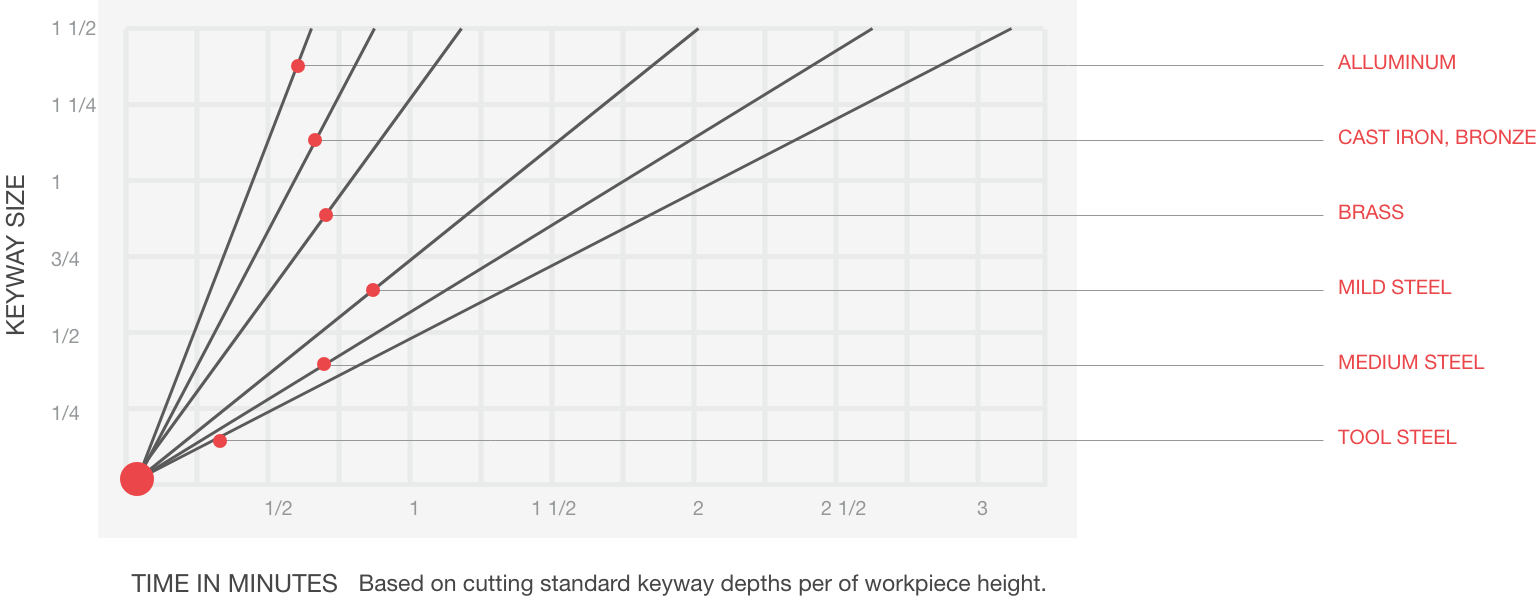

The chart illustrates cutting times for various size keyways and materials.

KEYWAY CUTTING

Case studies from the Model 15 Automatic

| Keyway Size: | 1/2″ wide x 1/4″ deep |

| Keyway Length: | 2″ |

| Material: | Cast Iron |

| Cutting Time: | 30 seconds |

| Keyway Size: | 1/4″ wide x 1/8″ deep |

| Keyway Length: | 2″ |

| Material: | Mild Steel |

| Cutting Time: | 25 seconds |

| Keyway Size: | 1/4″ wide x 5/8″ deep |

| Keyway Length: | 6″ |

| Material: | Tool Steel |

| Cutting Time: | 10 minutes |

METAL SLOTTING

Case studies from the Model 15 Automatic

All of the parts shown below have been slotted on a Model 15 Davis Keyseater (Automatic), and the times listed are superior to milling. The ability to cut external slots as well as internal keyways will make the Davis Keyseater one of the most versatile machines in your shop.

| Slot Size: | 3/16″ wide x 1-1/4″ deep |

| Slot Height: | 1″ |

| Material: | Mild Steel |

| Cutting Time: | 2 minutes total (2 slots) |

| Slot Size: | 3/16″ wide x .680″ deep |

| Slot Height: | 2-3/4″ |

| Material: | Cast Iron |

| Cutting Time: | 30 seconds |

| Rough Slot Size: | 5-8″ wide x 1-1/4″ deep x 1″ high |

| Finished Slot Size: | 1″ wide x 1-1/2″ deep x 1″ high |

| Material: | C1040 steel forging |

| Cutting Time: | 1 minute |

THE HANSFORD DAVIS KEYSEATER

Using the multiple tooth cutter principle, the Davis Keyseater machine is fast cutting, precise, and easy to set up and operate.

Our cutters virtually eliminate the necessity of frequent re-sharpening, resulting in longer tool life. Often it is possible to drive the cutter at a constant speed, regardless of the material or the size of the keyway being cut.

Cutters made of high-speed tool steel with proper rake, clearance, and hardness cut efficiently. Using a work locating bushing ensures concentricity and allows for fast set-up of parts. Manual and automatic feed models are available.

Davis Keyseaters can cut keyways that range widely in depth and width, whereas hand broaches are limited.

Our keyseating machines are also able to accept simple fixtures for external shaping and slotting of workpieces that are conventionally milled. This feature, combined with the rugged machine design and cost-cutting tooling principle, makes the Davis Keyseater one of the most versatile machines in your shop.