WHAT IS A DIE HANDLER?

Hansford Die Handlers help you safely move dies from machines or to storing areas. The Hansford Die and Mold Handler is a versatile machine tool designed to meet today’s rigid requirements of extreme precision and absolute reliability.

REQUEST INFO ON REFURBISHED MACHINES

Call Now or Inquire Online

Example of a Previously Sold Refurbished Die Handler

- Factory Warranty Included

- Fully Refurbished, Fully Functional

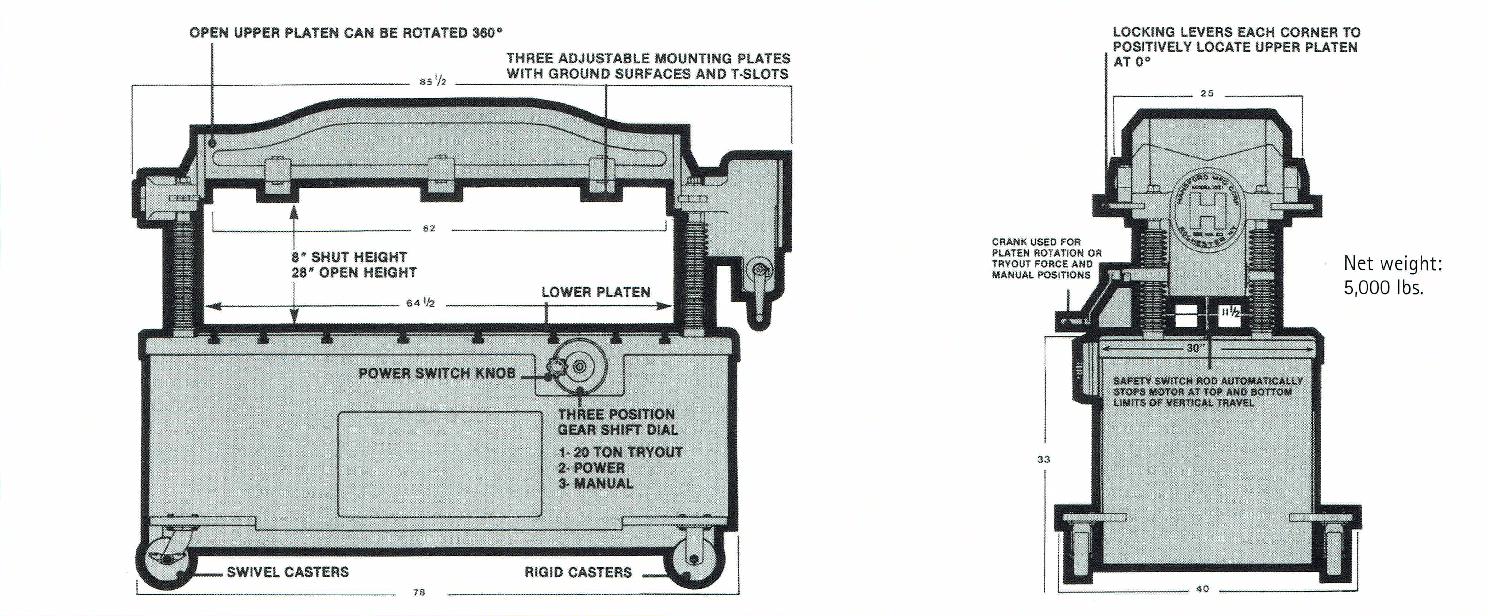

THE MODEL 1021

The Model 1021 Die Handler has a capacity of 3000 lbs.

The top platen is supported on ground steel trunnions and is rotatable through 360°. It is moved vertically by four precision lead screws driven by alloy bronze nuts supported in precision ball bearings. Levers at each corner lock it rigidly and accurately in the 0° and 180° positions. The open construction of this platen gives maximum access to the top of the die set.

A special gear change dial provides the ultimate in safety and ease of operation. Three positions are provided:

- “MANUAL,” where movement of the top platen is accomplished by hand crank

- “TRY-OUT” which provides tremendous gear reduction to allow a 20-ton force to be exerted between platens by hand crank

- “POWER” where an instantaneously reversible, 2 horsepower motor, controlled through a switch knob in the dial, raises a 3000-pound load at the rate of 13 inches per minute. A safety switch rod automatically stops the motor at the upper and lower limits of the top platen travel.

With the dial in the “POWER” position, the hand crankshaft is disengaged from the motor drive. With the dial in either the “MANUAL” or “TRY-OUT” position, the “POWER” switch is not operable.

Eliminate the hazards of slipping and jamming and increase your productivity by enabling one person to separate, service, and try-out valuable dies. Using chain hoists, lead mallets, and two or three toolmakers is not an efficient way to separate and service dies. Dies pulled from storage are usually separated and the punches, dies, and strippers are inspected before the die set is put in use.

If a die set has been in storage for several months, it may need relubrication. A die handler helps make die set inspection a fast and safe one-person operation.

The rugged, cast upper platen and lead screws utilized in Hansford Die Handlers assure a positive, smooth vertical movement and the ability to withstand the forces involved without deflecting beyond acceptable limits.

Today’s die sets are more complex and therefore, more care is needed to separate or close them without jamming. The rugged precision of the Hansford Die Handler eliminates problems of separation because the upper and lower platens are held parallel to each other within .003″ T.l.R., and ground locks are provided on all four corners of the upper platen.

All models have a rated try-out force which is exerted by hand crank in the “Try-Out” mode. This is a squeeze-type force, which allows some plants to shear in blanking dies. With a die separated and positioned, sharpening can be easily accomplished. Similarly, a forming die requires spotting in order to assure the proper match of the two halves, and this can be accomplished just as easily as shearing in or sharpening operations.

MODEL 1021 SPECIFICATIONS

| Shut Height | 8″ (Minimum Distance Between Platens) |

| Open Height | 28″ (Maximum Distance Between Platens) |

| Platen Areas | Lower: 30″ x 64″ long Upper: Adjustable Mtg. Plates |

| Mounting of Dies | Lower: 8—T Slots 30″ Long, for 3/4 ” bolts Upper: 6—Slots 8-1/2″ long, for 3/4 ” bolts (Adjustable) |

| Movement of Upper Platen | Vertical Travel: 20″ |

| Vertical Movement (By Hand Crank) | Manual Position: 48 Turns/inch Try-out Position: 384 Turns/inch |

| Vertical Movement (Power) | 13″/min. |

| Rotation of Top Platen | 240 Turns/360° |

| Motor | 2 H.P. 220/440 Volts, Three Phase, 60 Cycle, 1750 RPM, Instantaneously Reversing. |

| Control | Furnished with magnetic reversing starter with 110V at the controls |

| Capacity | 3000 Pounds (Maximum Die Weight Recommended) |

| Locking Position of Upper Platen | 0° & 180° |

| Maximum Die Try-out Force | 20 Tons |

| Net Weight | 5000 lbs. |

| Shipping Weight | 5200 lbs. |

J.I.C. standards furnished at extra cost.

Special voltages, and frequencies also available at additional cost.

For increased open height and platen travel, see list of accessories in price list DHS-2A.

Tell us about your challenges, you’ll like our solutions.

THE MODEL 1020

Model 1020 is no longer in active production; however, we will perform special runs for large scale orders. If you already have Model 1020 and are looking for maintenance, we are still happy to perform repair and rebuild services.

MODEL 1020 SPECIFICATIONS

| Shut Height | 8″ (Minimum Distance Between Platens) |

| Open Height | 28″ (Maximum Distance Between Platens) |

| Platen Areas | Lower: 24″ x 44-1/2″ long Upper: Adjustable Mtg. Plates |

| Mounting of Dies | Lower: 6—T Slots 24″ Long, for 3/4 ” bolts Upper: 4—Slots 8-1/z ” long, for 3/4 ” bolts (Adjustable) |

| Movement of Upper Platen | Vertical Travel: 20″ |

| Vertical Movement (By Hand Crank) | Manual Position: 48 Turns/inch Try-out Position: 384 Turns/inch |

| Vertical Movement (Power) | 13″/min. |

| Rotation of Top Platen | 48 Turns/360° |

| Motor | 1.5 H.P. 220/440 Volts, Three Phase, 60 Cycle, 1750 RPM, Instantaneously reversing. |

| Control | Furnished with magnetic reversing starter with 110V at the controls |

| Capacity | 3000 Pounds (Maximum Die Weight Recommended) |

| Locking Position of Upper Platen | 0° & 180° |

| Maximum Die Try-out Force | 20 Tons |

| Net Weight | 3350 lbs. |

| Shipping Weight | 3500 lbs. |

J.I.C. standards furnished at extra cost.

Special voltages, and frequencies also available at additional cost.

For increased open height and platen travel, see list of accessories in price list DHS-2A.