Last fall, we added Fiber Laser Cutting technology to our equipment profile.

The ENSIS Series Fiber Laser can cut steel, mild steel, stainless steel, aluminum, titanium, brass, copper, and other shiny metal materials up to four times faster than a CO2 laser.

This new addition to our contract machining capabilities supports our commitment to creating the best possible efficiencies for our customers.

Accurate and Efficient Metal Component Production

The precision, speed, and efficiency of metal laser cutting is perfect for high

production runs of a variety of OEM and OEM-equivalent metal parts.

Metal laser cutting is also great for short-run production needs. With simple, digital controls, plus no cutting lens change or manual setup required, preparing any size job is quick and easy.

How Fast is Metal Laser Cutting?

Turnaround time for the machine is exceptionally quick. Using the new fiber laser cutting system, our team can produce custom precision parts and turnkey products in much less time than before.

Turnaround time for the machine is exceptionally quick. Using the new fiber laser cutting system, our team can produce custom precision parts and turnkey products in much less time than before.

For example, we were able to cut a customer’s order in less time than an eight hour shift. The same order would have needed two weeks to run on our turret machine. The fiber laser allows us to meet tight customer turnaround times, while completing orders with less waste, fewer secondary operations, and less labor time. This allows us to move on to the next job, and meet or exceed the lead time for the next customer.

The Versatility of Custom Metal Laser Cutting

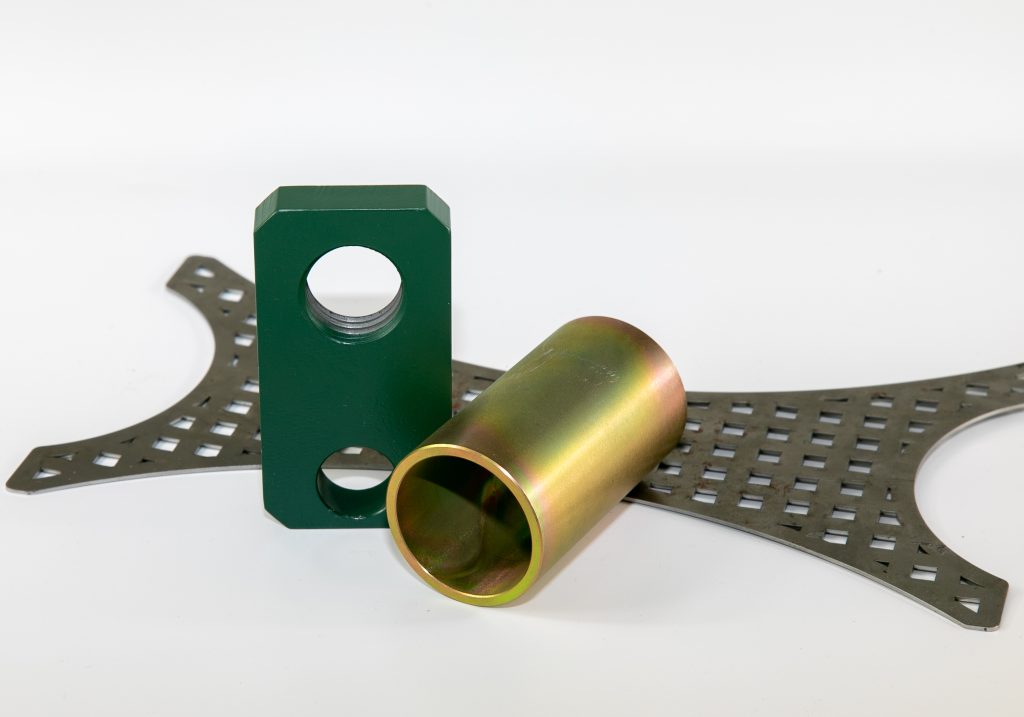

Our metal laser cutting service extends across a variety of shiny metal materials for a variety of different applications. To name a few, our team runs orders for control boxes, foot rests, blower housings, scroll cage fans, wire loom brackets, metal brackets, control panel electrical boxes, undercarriage protectors, shopping cart wheel brackets, and more.

Metal laser cutting can be used to create products and components across many industries, including transportation, automotive, optics, aerospace, medical, military, and communications.

Additional Benefits of Metal Laser Cutting

Other benefits of metal laser cutting include:

- Less wasted metal

- A lower production cost

- Minimal warping of material

- Precise cutting of metal

- The ability for cutting complex contours and intricate shapes

- A small heat affected zone

- No need for physical contact with the metal workpiece

Discover Metal Laser Cutting for Your Business

Ready to witness it for yourself? Check out this video to see our new metal cutting fiber laser in action.

If your business needs to explore options for machining cut metal products and parts, we’d love to chat with you. Contact us today to learn more about Hansford Parts and Product’s custom metal laser cutting services.